Researchers solve issues hindering silicon use in lithium-ion batteries

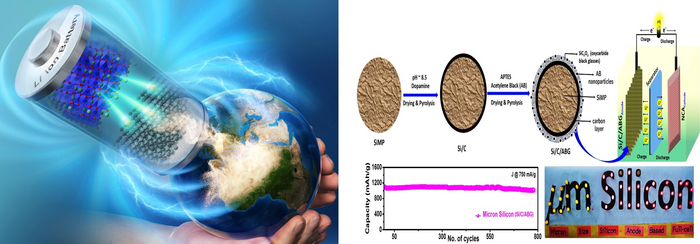

In a paper published in the Journal of Materials Chemistry A, the JAIST team reported a holistic approach to synthesizing novel and highly resilient SiMPs consisting of black glasses (silicon oxycarbide) grafted silicon as anode material for lithium-ion batteries.

“Silicon nanoparticles might provide increased effective surface area but that comes with its own drawbacks like increased consumption of electrolyte as well as poor initial coulombic efficiency after a few cycles of charging and discharging,” research lead Noriyoshi Matsumi said in a media statement.

“SiMPs are the most appropriate, low-cost, and easily available alternatives, especially when combined with materials that have exceptional structural properties, such as silicon oxycarbide black glasses.”

Matsumi explained that the team designed a core-shell type material where the core was made up of SiMP coated in a layer of carbon and then the silicon oxycarbide black glasses were grafted on as the shell layer.

The prepared materials were then used in an anodic half-cell configuration to test their ability to reversibly store lithium under different potential windows.

The screening showed that the material has great lithium diffusion ability and reduced internal resistance and overall volumetric expansion. It also showed a 99.4% retention of energy capacity even after 775 cycles of charging and discharging. In addition, the material exhibited great mechanical stability throughout the testing process.

In the scientists’ view, these results have opened up new pathways for the application of silicon in next-generation secondary lithium-ion batteries.

Matsumi pointed out that the upscaling ability of this synthesis process can help bridge the gap between laboratory research and industrial applications in the field of energy storage. This is particularly important for producing low-cost electric vehicles.

“Our methodology offers an effective avenue for the development of high-performance anode materials for energy-efficient lithium-ion batteries, which is an essential building block towards creating a sustainable and low-carbon tomorrow,” he said.

This post has been syndicated from a third-party source. View the original article here.